Xiaomi Electric Precision Screwdriver Kit (New)

- Two-speed torque adjustable

- Magnetic storage container

- 24 x S2 steel precision screwdriving bits

- 400+ precision screws on one full charge

Out Of Stock

36013

Xiaomi

Xiaomi Electric Precision Screwdriver

Xiaomi Electric Precision Screwdriver

Two-speed torque precise control, discover unlimited possibilities

Two-speed torque adjustable

Magnetic storage container

24 x S2 steel precision screwdriving bits

400+ precision screws on one full charge

Push pop-up , magnetic Storage Classic award-winning design

The Mi Precision Screwdriver has won five international

design awards; namely the iF, Red Dot, Japan Good

Design, IDEA and Chicago Good Design awards. The

Xiaomi Electric Precision Screwdriver uses the same popup

design, featuring a convenient, push-to-release

mechanism.

* The image on the left shows the Xiaomi Electric Precision

Screwdriver, and the image on the right shows the Mi Precision

Screwdriver. This image is used only to illustrate the different

dimensions of the two products.

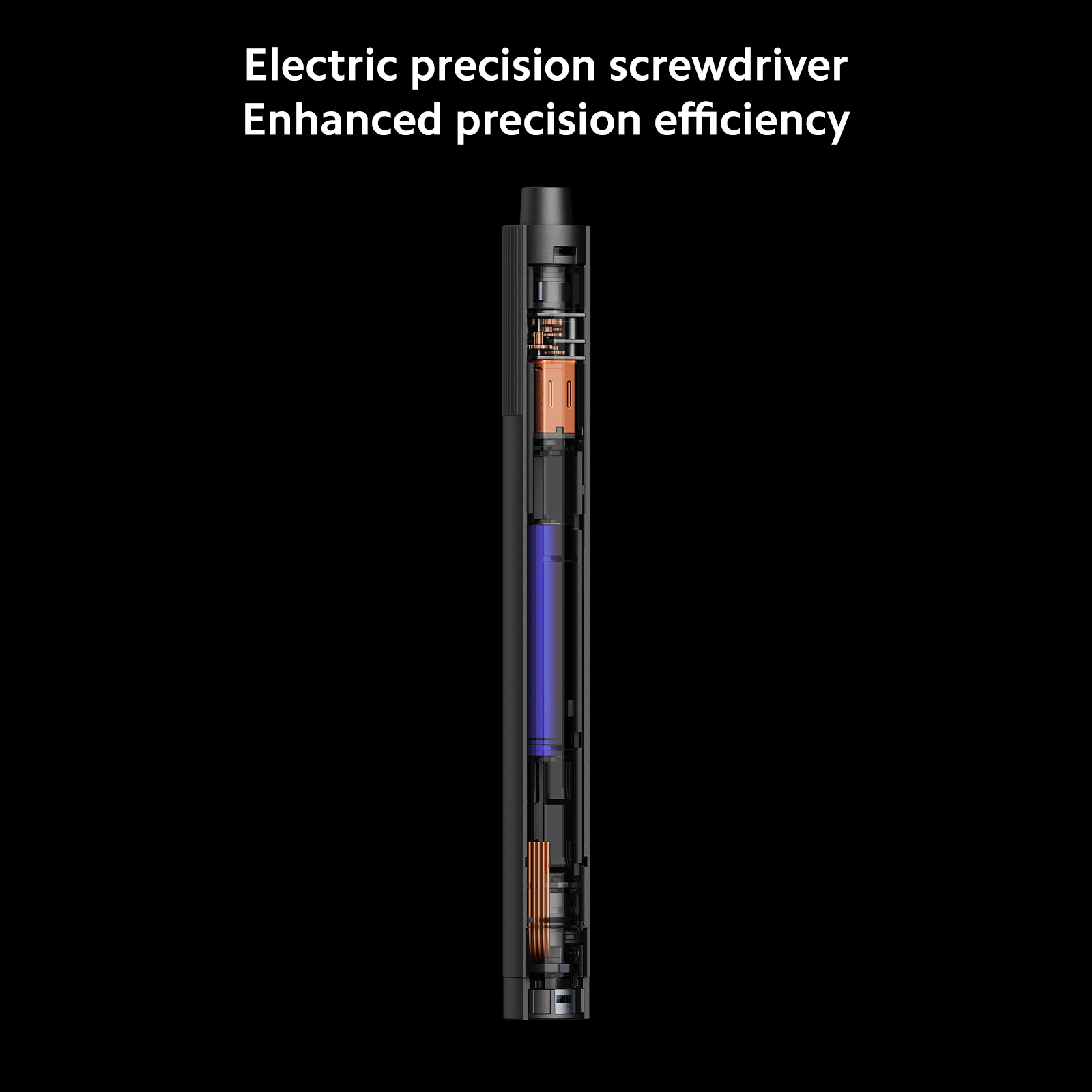

Electric precision screwdriver Enhanced precision efficiency

Thanks to the powerful magnetic motor with a speed of up to

170rpm*. and the all-metal gearbox, the screwdriver has a

screwdriving bit concentricity of no more than 0.2mm* when

rotating, for greater precision efficiency.

Compact design with an extra-long battery life 400+ precision screws on one full charge

The screwdriver has a shaft diameter of just 16.4mm*. The built-in rechargeable lithium battery is powerful and long-lasting and can process 400+ precision screws on one full charge*.

* Artistic rendering of the interior construction, which does not correspond exactly to the actual interior.

24 x S2 steel precision screwdriving bits in 9 major types

The 24 x high-quality S2 tool steel screwdriving bits are durable and tough and

have a hardness of up to 60HRC*.

The 24 types of precision screwdriving bit are ideal for dismantling and assembling

most standard electronics and new small household appliances.

6 commonly used 45mm long screwdriving bits for complex deep-hole applications

6 commonly used screwdriving bits out of the 24 are 45mm long for use

in a wide range of complex applications, such as deep holes and narrow

spaces.

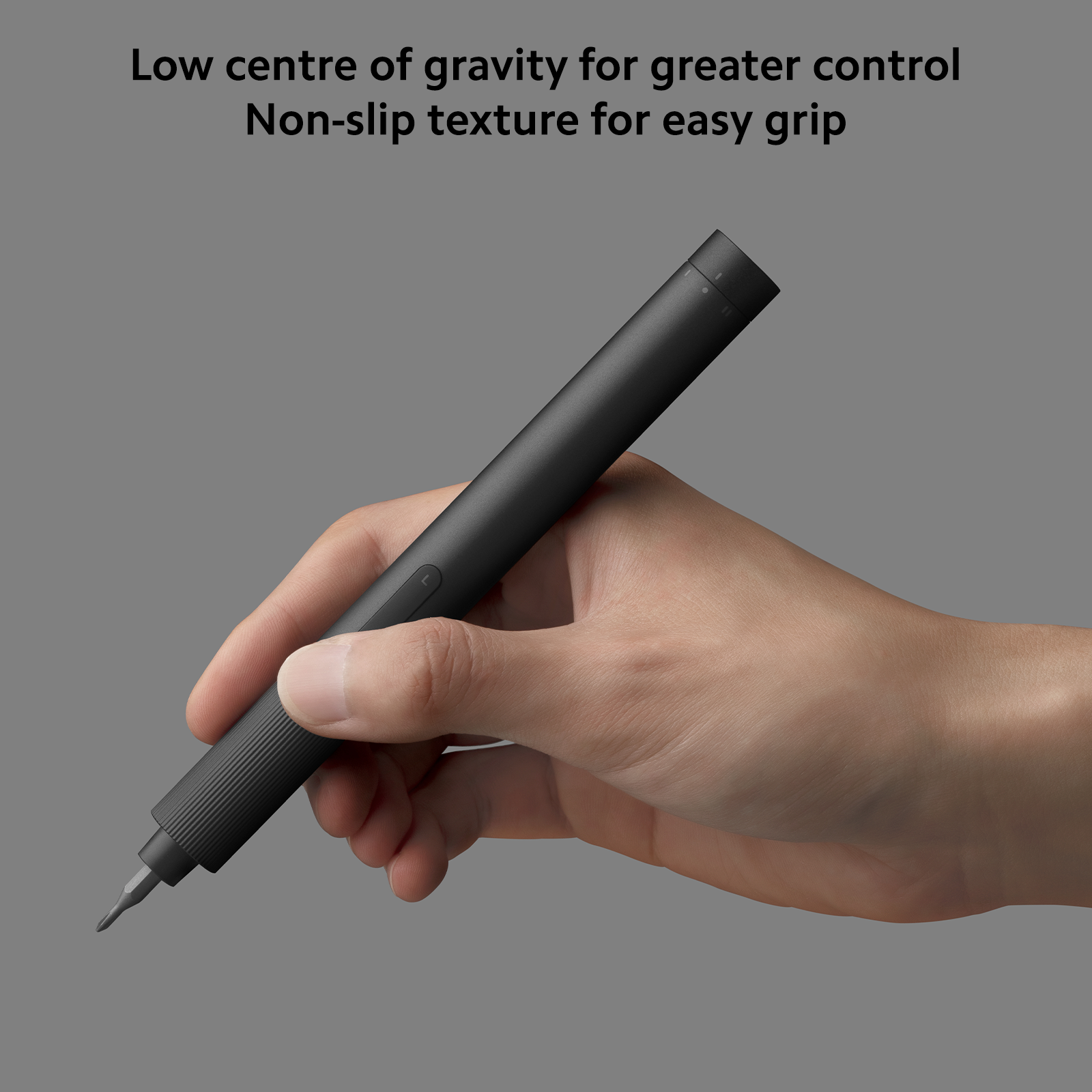

Low centre of gravity for greater control Non-slip texture for easy grip

The internal structure of the main body of the screwdriver has

been adjusted over and over to provide a balanced centre of

gravity and improved handling. The 3D non-slip texture on the

grip increases friction for a more secure hold of the screwdriver

during use.

Unibody aluminium alloy case Aluminium alloy anodising process

The storage case and the screwdriver body are both made of high-quality

aluminium alloy, making them comfortable to hold. The anodised surface

finish is non-slip and sweat resistant, and is less prone to rust.

Universal Type-C charging port Worry-free charging alert indicator

The Type-C charging port is compatible with charging cables of popular electronic products, making charging more convenient. The indicators next to the charging port instantly alert you when the battery is low and display the charging status.

* Speed test method: The fully charged device is run at no load for 2 minutes and the speed is then tested with an infrared tachometer.

* Spindle runout (i.e. precision bit concentricity) test method: A standard test rod is inserted into the output shaft. A laser diameter gauge is used to measure the runout at a distance of 25.4mm from the end surface of the output shaft.

* The dimensions stated may vary or be inaccurate due to different measurement conditions.

* Screwing test method: The device is fully charged until the white lamp is illuminated. The ST2 x 5mm self-tapping screw is then driven into the pine board until the battery runs out.

* Hardness varies by ±2HRC. Screwdriving bit hardness tests were conducted by the National Light Industry Tool Hardware Quality Supervision & Testing Station, Shanghai. Report No.: G20200215.

* Torque at level I varies by ±0.03Nm and torque at level II varies by ±0.08Nm. Torque test method: The fully charged device is run without load for 2 minutes and a torque tester is then used to measure the torque at levels I and II.

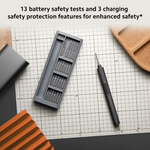

* The battery was tested by the Southern Testing Company of the China Certification & Inspection Group. Report No.: SET2019-08673. The battery protection tests were conducted by Precise Testing & Certification (Guangdong) Co., Ltd.; Report No.: PTC20032303001S-GB01.

* Unless otherwise indicated, all data referred to on this page is from the HOTO Laboratory. Data may vary or be inaccurate due to differences in the objective environment and other factors.

![[Refurbished] Unagi Scooter Model One E500(only deliver to QLD/NSW/VIC/SA metro area)](http://shop.panmi.com.au/cdn/shop/files/ProductImage-MatteBlack_144bb881-659f-4b5c-ba04-7d3d0b437dc4_{width}x.png?v=1707374655)

![[Refurbished] Unagi Scooter Model One E350(only deliver to QLD/NSW/VIC/SA metro area)](http://shop.panmi.com.au/cdn/shop/files/ProductImage-2_021781d1-6bc0-40b4-8ffe-7fb14b992757_{width}x.png?v=1707398954)